In the rapidly expanding world of sound healing and meditation, singing bowls have become essential instruments for practitioners seeking transformative acoustic experiences. Yet beneath their growing popularity lies a fundamental choice that profoundly affects both user experience and cultural preservation: the decision between handmade and factory-produced singing bowls. This choice represents more than a simple purchasing decision—it embodies the intersection of cultural heritage, manufacturing technology, and personal values that influences everything from sound quality to spiritual authenticity.

Historical Background and Manufacturing Evolution

Traditional Handmade Heritage

Handmade singing bowl craftsmanship extends deep into Himalayan history, where skilled artisans developed sophisticated metallurgical techniques within cultural frameworks that understood instrument making as spiritual practice. These ancient craftsmen worked in the high valleys of Tibet, Nepal, and northern India, where centuries of cultural isolation fostered distinct regional styles reflecting local materials, cultural preferences, and spiritual traditions.

Family workshop traditions formed the backbone of traditional production, with knowledge passing through generations of dedicated craftsmen who guarded their techniques as precious cultural heritage. These workshops operated as cultural preservation centers where traditional knowledge, spiritual practices, and artistic excellence converged to create instruments carrying forward accumulated wisdom.

Factory Production Development

The industrialization of singing bowl production emerged in response to growing global demand that traditional workshop production could not satisfy. As Western interest in meditation and sound healing expanded, the limited output of traditional craftsmen proved insufficient for rapidly growing markets.

Modern manufacturing draws from advances in metallurgy, precision manufacturing, and quality control systems, enabling consistent alloy compositions and computer-controlled machinery that reduces time and skill requirements. This shift moved production from traditional Himalayan communities to modern manufacturing centers, prioritizing consistency and accessibility over individual character.

Manufacturing Process Comparison

Traditional Handmade Methods

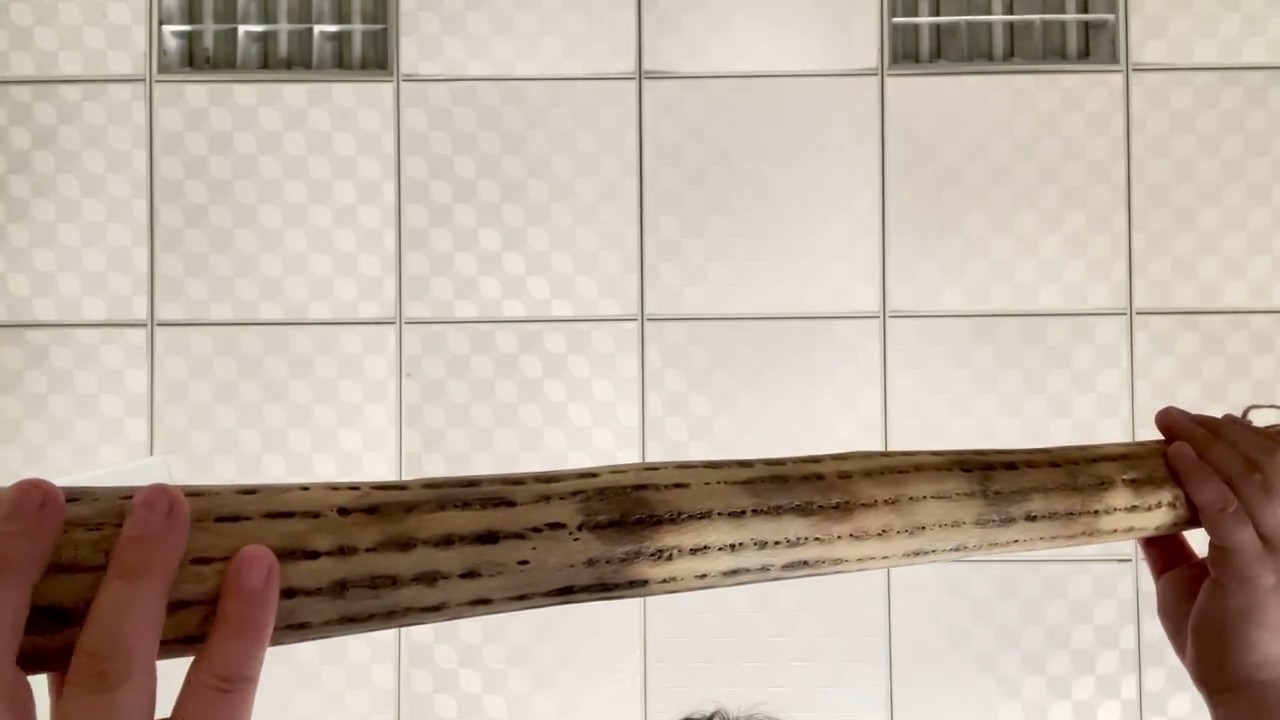

Recommend a video

Traditional creation begins with careful selection of raw materials, typically involving seven-metal alloys incorporating gold, silver, mercury, copper, iron, tin, and lead in proportions varying by regional traditions. Hand-melting using wood-fired furnaces creates temperature variations contributing to unique characteristics, with craftsmen monitoring through visual cues and spiritual guidance.

Hand-forging represents the heart of traditional creation, where skilled craftsmen transform bronze through thousands of precise hammer strikes. This process requires extraordinary sensitivity to metal response, with experienced makers adjusting technique based on acoustic feedback. The result creates subtle thickness variations throughout the bowl contributing to complex harmonic development impossible through mechanical methods.

Sound adjustment represents the final phase, where master craftsmen fine-tune acoustic properties through selective material removal and surface treatment, requiring extraordinary acoustic sensitivity and deep understanding of harmonic relationships.

Modern Factory Production

Contemporary factory production leverages materials science to create precisely controlled alloy compositions ensuring consistent acoustic properties. Industrial melting utilizes computer-controlled furnaces maintaining exact temperatures and atmospheric conditions, creating homogeneous bronze with predictable characteristics.

Mechanical forming employs hydraulic presses and precision machinery to shape bowls with exact specifications and consistent wall thickness. Computer-controlled machining enables precise finishing operations creating uniform surface textures across large quantities, while automated quality control monitors acoustic properties throughout production.

Material and Acoustic Differences

Alloy Composition

Traditional handmade bowls utilize seven-metal compositions with regional variations creating unique acoustic signatures. Higher copper content (60-80%) with varying ratios of other metals reflects local traditions and accumulated knowledge. Natural variations from hand-smelting contribute to acoustic complexity rather than compromising quality.

Factory production employs scientifically formulated alloys, often bell bronze compositions (78% copper, 22% tin) proven for acoustic excellence. Industrial purity standards ensure precise metal percentages while eliminating impurities, creating homogeneous alloys with uniform characteristics enabling predictable performance.

Sound Quality Characteristics

Handmade bowls exhibit rich harmonic complexity emerging from subtle thickness variations and natural material inconsistencies. These instruments typically demonstrate longer, more complex decay patterns with multiple resonant modes creating organic acoustic experiences that seem alive and responsive.

Factory bowls demonstrate standardized acoustic properties with predictable frequency responses and stable harmonic relationships. While potentially lacking individual character, their reliability and consistency serve educational, therapeutic, and musical applications requiring predictable behavior.

Visual and Craftsmanship Features

Handmade Characteristics

Traditional instruments display tool marks revealing craftsman technique, surface texture variations reflecting organic hand-forging, and slight asymmetries contributing to visual character. Traditional decorative elements including hand-engraved patterns serve both aesthetic and acoustic functions while connecting instruments to cultural traditions.

Factory Features

Factory instruments demonstrate geometric precision with exact dimensional specifications and uniform surface finishes achievable through mechanical processing. Consistent visual appeal and standardized characteristics facilitate matching sets while ensuring compatibility with specialized applications.

Quality Assessment and Market Positioning

Quality Standards

Handmade bowl assessment emphasizes harmonic complexity, sustain duration (typically 45+ seconds), and responsiveness demonstrating musical and therapeutic potential. Cultural authenticity involves examining construction details, material characteristics, and design elements aligning with traditional practices.

Factory quality focuses on technical specification compliance, acoustic precision, and manufacturing consistency across production runs. Systematic testing ensures predetermined acoustic parameters while batch consistency enables replacement availability and institutional applications.

Market Segments and Pricing

Professional sound therapists often prefer handmade instruments for exceptional acoustic characteristics and cultural authenticity enhancing therapeutic effectiveness. Collectors value traditional pieces for cultural significance and investment potential, while educational institutions typically favor factory instruments balancing quality with durability and cost considerations.

Pricing reflects manufacturing costs, cultural significance, and market positioning. Handmade instruments command premiums based on cultural heritage and individual character, while factory products offer accessible entry points with reliable performance at lower cost points.

User Experience and Applications

Playing and Therapeutic Differences

Handmade bowls often exhibit organic responsiveness seeming to react to player intention, creating intimate instrument-musician connections. Surface variations provide tactile feedback while unique weight distribution affects handling characteristics.

Factory instruments offer predictable handling with consistent weight distribution and surface textures facilitating technique development. Their standardized characteristics serve beginners and professional applications requiring reliable performance outcomes.

Therapeutic Effectiveness

Many practitioners report handmade instruments produce acoustic characteristics feeling more organic and alive, creating therapeutic experiences more connected to natural healing processes. The evolving harmonic content typical of traditional bowls maintains engagement throughout extended sessions.

Factory instruments provide consistency serving guided meditation and therapeutic protocols requiring predictable acoustic parameters, though they may lack the emotional resonance many find in traditional pieces.

Cultural Value and Sustainability

Cultural Significance

Handmade traditions represent living connections to ancient wisdom systems understanding sound as fundamental spiritual force. Supporting traditional craftsmen provides crucial income enabling continuation of cultural practices while participating in heritage preservation.

Factory production serves cultural democratization through affordable access while building awareness that may generate interest in traditional instruments. This accessibility introduces broader populations to singing bowl culture without requiring prohibitive investments.

Environmental Considerations

Traditional production typically involves smaller-scale operations with lower energy requirements and minimal waste generation. Local sourcing reduces transportation impacts while supporting traditional communities.

Factory production includes higher energy consumption but may achieve scale efficiencies reducing per-unit environmental impacts. Both approaches can support sustainability through quality construction ensuring long service lives.

Buying Guide and Recommendations

Selection Criteria

Choose handmade instruments when seeking:

- Maximum acoustic complexity and character

- Cultural authenticity and spiritual connection

- Professional therapeutic applications

- Collector value and investment potential

- Support for traditional craftsmanship

Select factory instruments when prioritizing:

- Consistent quality and reliability

- Educational and institutional applications

- Budget considerations and accessibility

- Matching sets and replacement availability

- Entry-level practice development

Authentication and Quality

Identify handmade characteristics through tool mark patterns, thickness variations, acoustic complexity, and cultural authenticity markers. Verify sources and request documentation when possible.

Recognize factory features through manufacturing uniformity, consistent dimensions, standardized surface finishes, and predictable acoustic properties across multiple instruments.

Future Trends and Innovation

Contemporary developments include hybrid approaches combining traditional techniques with modern quality control, preserving cultural authenticity while improving consistency. Technology-assisted traditional methods enhance production efficiency without compromising individual character.

Educational initiatives preserve traditional knowledge while building appreciation for both heritage and innovation. Collaborative projects between traditional craftsmen and modern manufacturers facilitate knowledge exchange serving broader cultural preservation goals.

Conclusion

The choice between handmade and factory singing bowls depends on individual needs, values, and applications rather than inherent superiority of either approach. Both serve crucial functions within the singing bowl community: traditional instruments preserve cultural heritage while providing exceptional acoustic experiences, while factory products democratize access and serve institutional needs.

For beginners, factory instruments often provide accessible entry points enabling skill development without substantial investment. Professional practitioners may require exceptional traditional characteristics, while collectors typically prefer authentic cultural pieces. Educational institutions often find factory instruments better suited for consistency and budget requirements.

The future likely involves continued coexistence of both approaches, each serving different community needs while contributing to cultural evolution and preservation. Supporting informed purchasing decisions helps ensure traditional knowledge continues while modern innovation serves contemporary applications.

Ultimately, quality singing bowls—whether handmade or factory-produced—continue offering pathways to greater awareness, healing, and spiritual connection that transcend manufacturing origins. The most important factor is finding instruments resonating with individual needs and values while providing meaningful contribution to personal development and cultural appreciation through the transformative power of sound.